Short Description:

$content.description

联系我们获取更多信息

联系我们获取更多信息

我们能为您提供更多的选择方案

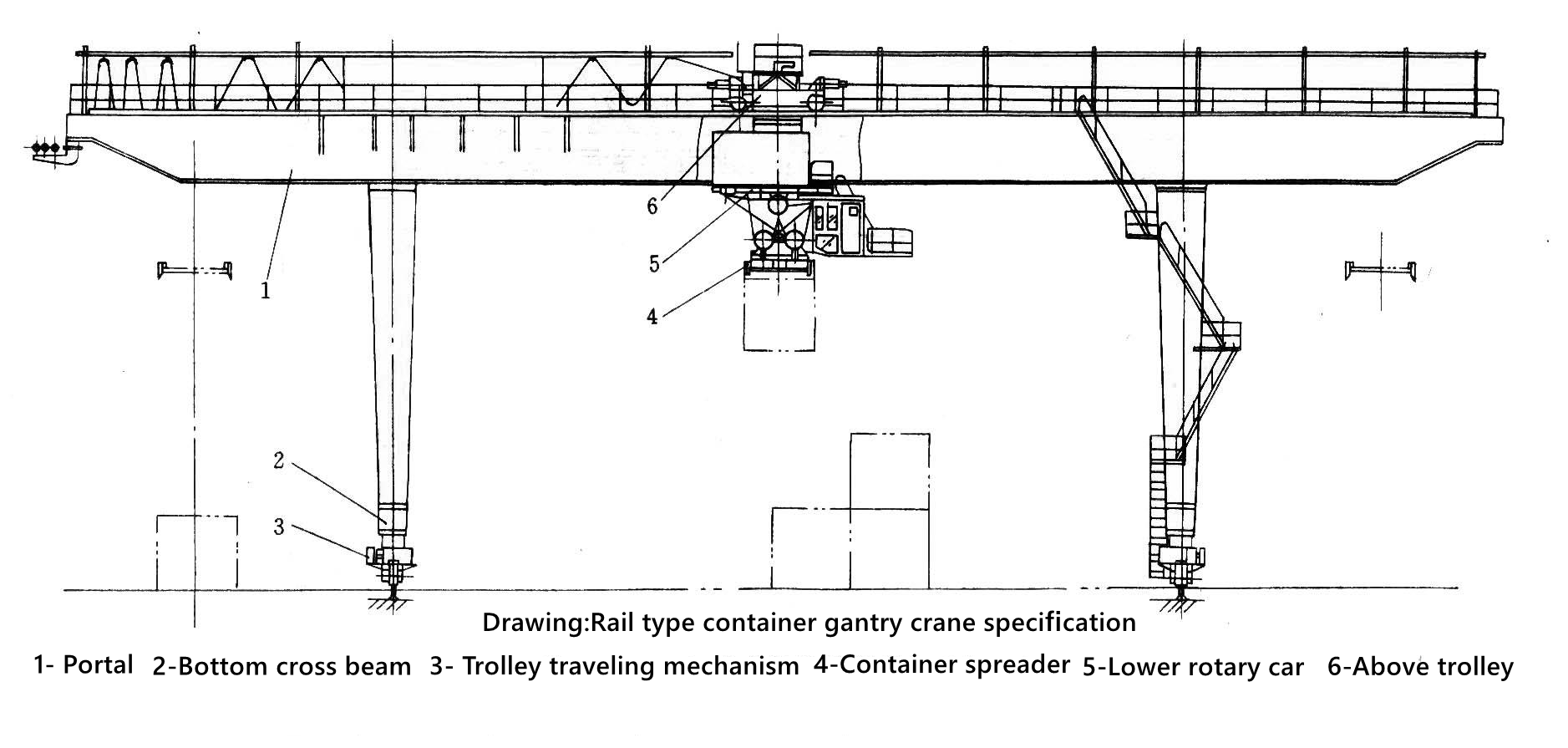

Rail-mounted container gantry crane

Rail-mounted gantry crane is a specialized container handling equipment, which is widely used in container yard loading and unloading operations such as coastal ports, inland ports, railway transit and chemical storage. The utility model has the advantages of excellent technical performance, high work efficiency, energy saving and environmental protection, low use cost, high site utilization rate, low investment, long service life and convenient operation and maintenance.

Characteristic

1.Lifting appliance flexible box holding technology

Adopt advanced software intelligent deceleration technology, cooperate with hardware detection and protection equipment, dynamically adjust the deceleration time and position in the case, reduce the impact on the equipment and the wheel pressure of the whole machine, and improve the service life and stability of the equipment.

2. Windbreak anchoring system

It is equipped with two sets of independent anchoring devices to resist horizontal force, four sets of windproof cables to resist overturning moment, and four sets of windproof crawlers or wheel clamps to ensure the stability of the whole machine. It can be equipped with electric iron wedge, wheel clamping device, rail clamping device, top rail device and other wind proof devices, which is convenient and reliable for operation.

3. Intelligent rectification technology of gantry

Through real-time detection of the frame deflection relative to the track, the deflection is used as the control signal to control the frequency converter to adjust the speed of the driving motor in real time, manually or automatically correct the frame deflection, so as to avoid the gantry gnawing the track, ensure the safe operation of the equipment, slow down the wear of the wheel and track, and improve the service life of the equipment.

Intelligent ,Efficient

1) New moment anti roll system

Through the reasonable arrangement of guide wheels in horizontal and vertical directions, the movement of four hoisting wire ropes in the space can effectively prevent the swing and torsion of the spreader and greatly improve the working efficiency of the lifting box.

2) Container automatic track and automatic lifting system

Through the storage, utilization and database management of the location information of each mechanism of the equipment and the container information of the storage yard, the automatic track operation and optimal track control of the mechanism are realized, and the working efficiency of the equipment is improved on the premise of ensuring safety.

Energy-Saving

1) Energy feedback technology

With the advanced active inverter technology, the kinetic energy and potential energy stored in the machine can be converted into electrical energy, which can be efficiently fed back to the power grid. At the same time, the pollution of high-order harmonic to the power grid is restrained, and the power factor of the whole machine is improved.

2) Intelligent low voltage capacitance compensation

Fully automatic dynamic harmonic elimination reactive power compensation device is configured to effectively improve the power factor of the equipment, which can reach more than 0.9, improve the quality of power consumption, reduce line loss, and achieve the purpose of energy conservation and consumption reduction.

Rail type container gantry crane specification

| Item | QRMG5508 | QRMG5530S | QRMG5540S | Recommended parameters | Optional range | |

| SWL under soreader(t) | 40 | 41 | 41 | 35、41、50、65 | 10-65 | |

| Span(m) | 35 | 30 | 40 | 30、40 | 15-50 | |

| Outreach(m) | 3/0 | 5/5 | 7.5/7.5 | 4.5、7.5 | 4-18 | |

| Hoist height(m) | 21 | 15.3 | 18.2 | 12.4 | 9.5-21.1 | |

| 15.3 | ||||||

| 18.2 | ||||||

| Hoist speed(m/min) | Empty load | 25 | 22 | 20 | 15、20、25、30 | 10-40 |

| Hoist speed(m/min) | Full load | 50 | 40 | 40 | 30、40、50 | 20-80 |

| Trollry travelling speed(m/min) | Empty load | 70 | 70 | 80 | 60、70、80、90 | 30-150 |

| Trollry travelling speed(m/min) | Full load | 70 | 100 | 100 | 60、70、80、90 | 30-150 |

| Gantry travelling speed(m/min) | Empty load | 40 | 50 | 50 | 40、50、60 | 30-120 |

| Gantry travelling speed(m/min) | Full load | 40 | 50 | 50 | 40、50、60、70、80、90 | 30-120 |

| Trollry slewing speed(m/min) | / | / | / | 1.0、1.1、1.2、1.3、1.4、1.5 | Only available for upper and lower trollry | |

| spreader slewing angle | 5 | 5 | 5 | -10~+270or-5~+5 | -10~+270or-5~+5 | |

| Power supply mode | Cable reel | Cable reel | Cable reel | Cable reel、Touch line | As per client's requirement | |

| Supply voltage | 6.6KW | 380V | 380V | 380V、10KW | 380V-10KW |